| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cold Runner Injection Molding |

|---|---|

| Brand Name: | Chitwing |

| Model Number: | Smart Watch |

| Certification: | ISO 9001:2015 |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 set/month |

| Delivery Time: | 30 day(s) |

| Packaging Details: | The mold is packaged with a wooden box and placed on a wood pallet. |

| Size: | 350.000 X 450.000 X 391.000 |

| IMM Tonnage: | 180T |

| Mold Weight: | 392kg |

| Mold base P/N: | GCI3045 10011090 |

| Tool life: | 500000 shots |

| Part material: | PC |

| Gate: | Side gate |

| Slide/Lifter: | 2/5 |

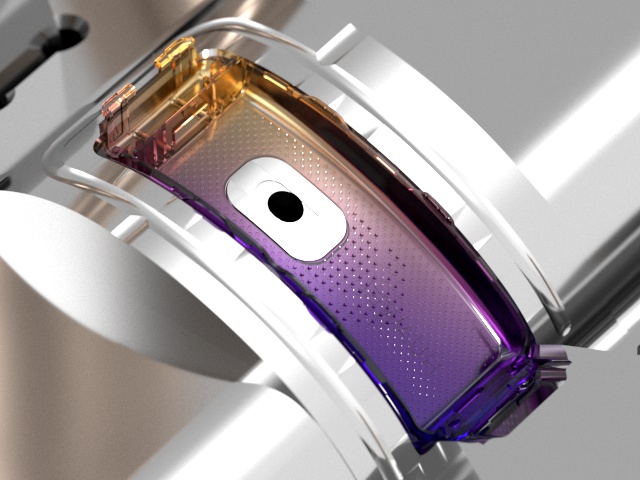

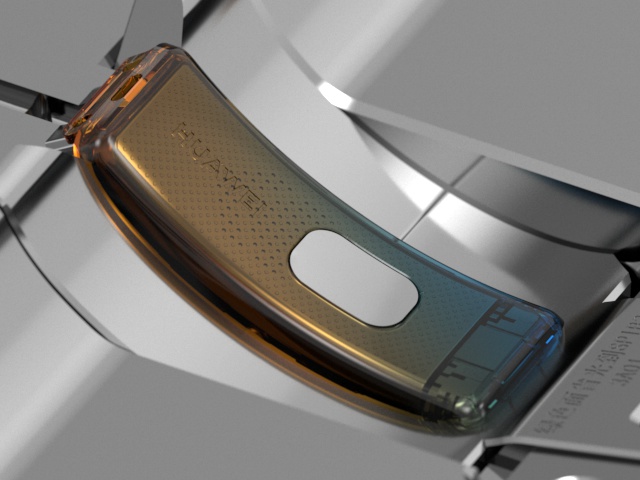

Transparent Smart Watch Base

Lower Housing (1*4)

No.23305

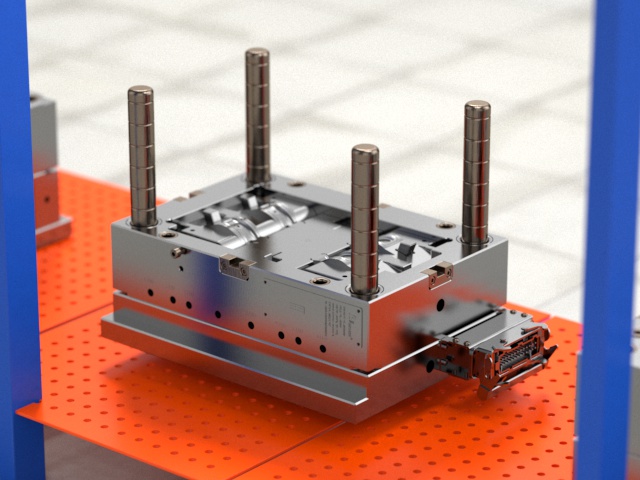

Introducing the mold with the part number GCI3045 10011090, it is a

three-plates mold with a size of 350x450x391 and a net weight of

392kg. Designed for an injection molding machine with a tonnage of

180T, it follows the LKM standard. The mold has a tool life of 500K

shots and features a side gate for injection. The part material

used is PC, with dimensions of 21.41 x 50.40 x 25.18mm and a net

weight of 1.6g. |

One of the key features of this mold is the hot runner system,

which offers cost savings, shorter molding cycles, and eliminates

condensed materials. It also provides a high degree of automation,

eliminating the need for post-processing and resulting in

significant savings in raw materials and labor costs. |

One of the key features of this mold is the hot runner system,

which offers cost savings, shorter molding cycles, and eliminates

condensed materials. It also provides a high degree of automation,

eliminating the need for post-processing and resulting in

significant savings in raw materials and labor costs. The mold surface is treated with A surface EDM using SPI-B1,

ensuring a glossy and smooth finish. This results in molded parts

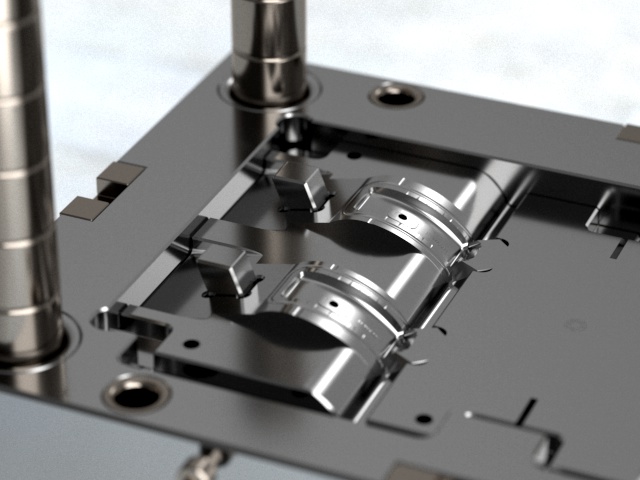

with smooth and clear surfaces. To enhance durability and meet the requirements of high-quality

mass production, the cavity and core of the mold are made of

hardened steel (1*4/S136). This steel has high hardness,

anti-abrasion, and anti-corrosion properties, ensuring a long tool

life. |

Additionally, the mold includes 2 slides and 5 lifters, adding

versatility and functionality to the mold design. |

Display diagram

Introducing the mold with the part number GCI3045 10011090, it is a

three-plates mold with a size of 350x450x391 and a net weight of

392kg. Designed for an injection molding machine with a tonnage of

180T, it follows the LKM standard. The mold has a tool life of 500K

shots and features a side gate for injection. The part material

used is PC, with dimensions of 21.41 x 50.40 x 25.18mm and a net

weight of 1.6g. One of the key features of this mold is the hot runner system,

which offers cost savings, shorter molding cycles, and eliminates

condensed materials. It also provides a high degree of automation,

eliminating the need for post-processing and resulting in

significant savings in raw materials and labor costs. The mold surface is treated with A surface EDM using SPI-B1,

ensuring a glossy and smooth finish. This results in molded parts

with smooth and clear surfaces. To enhance durability and meet the requirements of high-quality

mass production, the cavity and core of the mold are made of

hardened steel (1*4/S136). This steel has high hardness,

anti-abrasion, and anti-corrosion properties, ensuring a long tool

life. Additionally, the mold includes 2 slides and 5 lifters, adding

versatility and functionality to the mold design. |

|