| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Mining Machine Spare Parts |

|---|---|

| Brand Name: | ZTIC |

| Model Number: | Mining Machine Spare Parts |

| Certification: | ISO/CE |

| Place of Origin: | Henan, China |

| MOQ: | >=1 Tons |

| Price: | negotiable |

| Supply Ability: | 1000 Ton/Tons per Month |

| Packaging Details: | Standard packing or according to customer's requirement |

| Model: | Spherical Ceramic Sand |

| Main Chemical Component: | Al.O:70~85%,Fe,O,≤5% |

| Shape: | Good spherical |

| Thermal conductivity (100~1000°℃): | 0.35~0.50 W/mK |

| Particle Size: | 0.053mm~2.50mm |

| Lin.exp.coeff. (20~600°℃,10⁸ ×K'): | 7.2 |

| Thermal Expansion: | 0.13%(10 minutes at 1000℃) |

| Type: | Mining Machine Spare Parts |

| Company Info. |

| Luoyang Zhongtai Industries CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Casting used Ceramsite Spherical Ceramic Of Mining Machine Spare Parts

1. Spherical ceramic sand for foundry Of Mining Machine Spare Parts

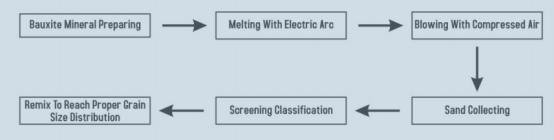

In order to reduce waste emissions and health hazards to people in classic foundry process, as well as to improve foundry efficiency, Luoyang Kailn Foundry Material Company has developed a new special foundry sand, ceramic sand.

Due to ceramic sand outstanding properties, ceramic sand has been widely used in most types of foundry process as an upgrade substitution of silica sand and special foundry sands.

Ceramsite Spherical Ceramic Of Mining Machine Spare Parts

2. CERAMIC SAND Characteristic Of Mining Machine Spare Parts

Anti Burn-on

High Reclamation Yield

Thermal Expansion Control

Wide Choice of Particle Size

Reduced Waste and Health Hazard

Good Flowability and Heat Conductivity

Low Resin Consumption and Gas Defects

| Main Chemical Component | Al.O:70~85%,Fe,O,≤5%,TiO.:3~4%,SiO::12~25% |

| Shape | Good spherical |

| Angularity Facto | ≤1.1 |

| Particle Size | 0.053mm~2.50mm |

| Bulk Density | 1.95~2.051(g/cm³) |

| Thermal Expansion | 0.13%(10 minutes at 1000℃) |

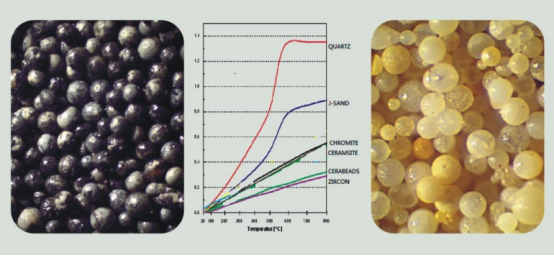

Properties(compare with other foundry sand)

| Ceramic sand | Quartz sand | Chromite | Zircon | Cerabeads | |

| Refractoriness | 1800℃/3272°F | 1730℃/3146°F | 1880℃/3416°F | 1825℃/3317F | 1825℃/3317°9 |

| Bulk density (g/cm³/b/ft') | 2/124 | 1.58/99 | 2.81/175 | 2.95/187 | 1.69/106 |

| pH | 7.3 | 6.6 | 7.9 | 5.7 | 7.2 |

Thermal conductivity (100~1000°℃) | 0.35~0.50(W/mK | 0.255(W/mK) | 0.258(W/mK) | 0.305(W/mK) | 0.223(W/mK) |

Lin.exp.coeff. (20~600°℃,10⁸ ×K') | 7.2 | 23 | 7.5 | 4.1 | 4.0 |

| Mohs' hardness | 6.5~7.5 | 6.0~7.0 | 5.5~6.0 | 7.0~8.0 | 5.0~5.5 |

| Mineralogical composition | Mullite+Corundum | Quartz +Feldspar | Chromite | Zircon | Mullite (sintered mulite) |

| Grain shape | Spherical | Angular | Angular | Semi-angula | Spherical |

Ceramsite Spherical Ceramic Of Mining Machine Spare Parts

3. Parts of papticle size distribution Of Mining Machine Spare Parts

| spec. | AFS30 | AFS40 | AFS50 | AFS60 | AFS65 | AFS75 | AFS100 | AFS125 | AFS150 | |

| mesh | micron | |||||||||

| 10 | 1700 | |||||||||

| 14 | 1180 | |||||||||

| 18 | 850 | ≤5 | ||||||||

| 26 | 600 | 15~30 | ≤5 | ≤5 | ||||||

| 36 | 425 | 30~50 | 20~40 | 10~25 | ≤10 | ≤5 | ||||

| 50 | 300 | 20~35 | 25~40 | 25~35 | 15~35 | 10~25 | ≤10 | |||

| 70 | 212 | ≤10 | 10~30 | 25~35 | 25~35 | 15-30 | 10~30 | ≤3 | ≤2 | |

| 100 | 150 | ≤5 | ≤10 | 5~25 | 25~35 | 25~40 | 25~45 | 10~30 | 0~20 | ≤5 |

| 140 | 106 | ≤5 | ≤10 | 5~20 | ≤25 | 20~40 | 35~55 | 30~50 | 5~25 | |

| 200 | 75 | ≤2 | ≤5 | ≤5 | ≤10 | 15~35 | 25~45 | 40~60 | ||

| 281 | 53 | ≤1 | ≤1 | ≤1 | ≤5 | ≤10 | 0~20 | 25~35 | ||

| PAN | PAN | ≤0.5 | ≤0.5 | ≤0.5 | ≤2 | ≤5 | ≤15 | |||

AFS average finess range | 25~35 | 35~45 | 45-55 | 55-65 | 60-70 | 70~80 | 95~110 | 120~135 | 145~165 | |

Ceramsite Spherical Ceramic Of Mining Machine Spare Parts

|