| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Steel Grating Welding Machine |

|---|---|

| Brand Name: | MLG |

| Model Number: | MLG-1200 |

| Certification: | CE |

| Place of Origin: | Hebei China |

| MOQ: | One set |

| Supply Ability: | 4--5 sets per month |

| Delivery Time: | 30 days after receiving deposit or L/C. |

| Packaging Details: | wooden pallet and plastic package in the container. After-sales service: We offer installation and train the workers for the customers. Our guarantee time: one year since the machine was installed at buyer's factory but within 18 months against B/L date. |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Product name: | steel bar grating spot welding equipment |

| Width of grating: | Max 1200mm |

| length of grating: | Max 6000mm |

| Pitch of flat bar: | 2.5*25mm--6*65mm |

| pitch of cross bar: | 6--8mm |

| name: | steel plate welding machine |

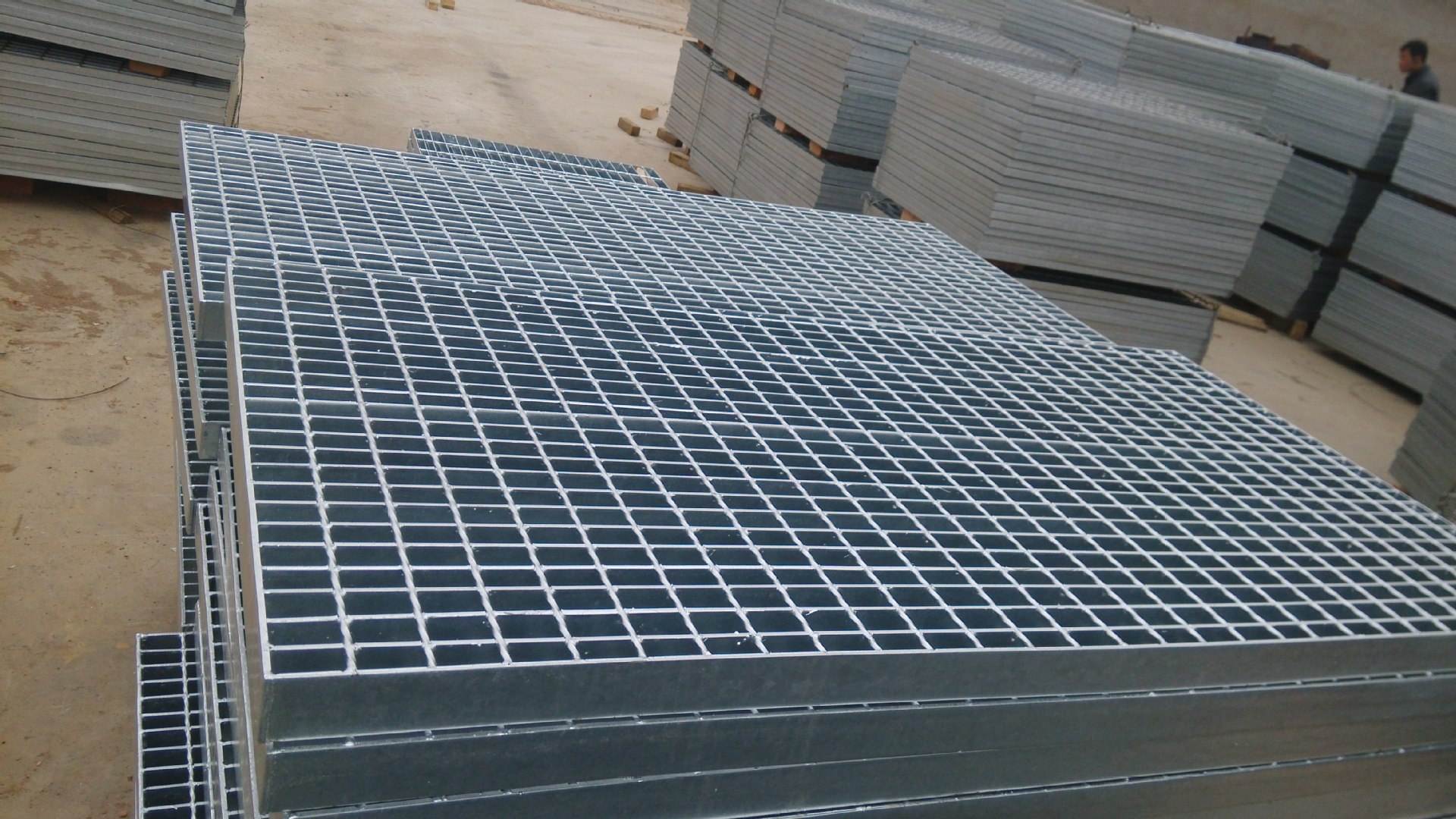

High Speed Steel Plate Mesh Welding Machine With High Degree Automation

1. Brief introduction:

Automatic steel plate mesh welding machine is a concentration of

electric, hydraulic, resistance welding, machinery, etc., as one of

the large welding equipment.With compact structure, welding strong

function, high degree of automation, product quality, convenient

operation and maintenance, strong productivity, etc.Intermediate

frequency welder frequency is 1000 hz, large output current

density.The secondary loop output impedance is small, welding

current, low dissipation electrodes directly connected to the

rectifier circuit, greatly saves the energy required during

welding.

1. The machine include below: flat rack, hydraulic mold, servo

stepper institutions, medium frequency transformer, host,

intermediate frequency welding controller, control system.

2. Bonding host equipment structure, function and characteristics.

01, Twisted steel artificial planted, automatic into the material.

02, Flat steel manual locate

03, Automatic welding.

04, Before and after automatic distance control table.

05, Equipment parameter setting, using intelligent digital display.

06,Equipment, manual and automatic control.Operators can overcome

the welding process changes brought about by the adverse factor,

the operation is simple and convenient.

07, New design of the structure of a 200 kva transformer can

production, to achieve the requirement of the pressure

welding.Compared to large welding machine with 800 KVA transformer

small investment.

The microcomputer controller

Products in Chinese liquid crystal microcomputer controller, the

stable welding current, ensure the solder joints of beautiful,

strong fastness.

In circulating cooling water system

The cooling circulating water with high water or water temperature

automatic alarm., keep water temperature is less than 30 degrees,

pure quality, so as not to reduce leakage and cooling water

plugging.

Main features:

1. Adopts Japan Mitsubishi PLC program and touch screen to control.

2. This machine adopts hydraulic device to control welding

electrode; it can weld 3 points per time when flat bar thickness is 2.5-3mm,weld2 points per time when flat bar thickness is 3-5mm.weld 1point per time when flat bar thickness is 5-6mm.

3. The mesh pulling system adopts Japan Mitsubishi Panasonic servo motor, more stable, high precision.

4. This machine adopts specially designed mold to fix flat bars.

The flat bar space is fixed, flat bar thickness and width can be

adjusted within range on one mold.

5. The welding transformers are water cooling type.

6. Feeding way: the flat bar should be put by the worker; the twist

bar should be straightened.

Technical parameter

| Bearing flat bar | 2.5*25-6*65mm |

| Cross bar | 5*5-8*8mm |

| Grating width | Max1.2m |

| Grating length | Max.6m |

| Pitch of flat bar : | 25-60mm |

| Pitch of cross bar: | 50-200mm |

| Needed power | Min.160kva |

| Production Capacity | 30-100M2/shift (8hours ) |

| Welding transformer | 250kva*2pcs |

| Overall size: | 16*2.5*1.5M |

| Weight : | 4000kg |

|