| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | SMT cleaning machine |

|---|---|

| Machine Type: | HIGH PRESSURE CLEANER |

| Applicable Industries: | electronic factory |

| Condition: | New |

| Place of Origin: | Guangdong, China |

| Brand Name: | ME-5600 off-line PCB/PCBA Cleaning Machine |

| Use: | PCBA Cleaning Machine |

| Cleaning Process: | PCBA Cleaning Machine |

| Cleaning Type: | Industrial Ultrasonic Cleaner |

| Industry Used: | Electronic Industry |

| Material: | PCBA Cleaning Machine |

| Power: | Pneumatic Stencil Cleaner |

| Dimension(L*W*H): | L1300 x W1200 x H850(mm) |

| Warranty: | 1 Year |

| Max. Pressure: | PCBA cleaner |

| Marketing Type: | PCBA cleaner |

| Machinery Test Report: | PCBA cleaner |

| Video outgoing-inspection: | PCBA cleaner |

| Warranty of core components: | PCBA cleaner |

| Core Components: | PCBA cleaner |

| Key Selling Points: | PCBA cleaner |

| Weight (KG): | 600 kg |

| Product name: | off-line PCB/PCBA Cleaning Machine |

| Power/Air supply: | AC380V/50A/50HZ,30KW,0.5Mpa |

| Cleaning basket size: | L610 x W560 x H100 (mm) x2 layers |

| Spray tank capacity: | 17L |

| Concentrate capacity: | 32L |

| Dilution capacity: | 60L |

| Clean time: | 5~20min |

| Rinse time: | 1~2min/times |

| skype: | sensenhenhao |

| whatsapp/wechat: | +8613424013606 |

| Packaging Details: | off-line PCB/PCBA Cleaning Machine package+plywood case |

| Port: | shenzhen |

| Supply Ability: | 100 Set/Sets per Month off-line PCB/PCBA Cleaning Machine |

| Price: | $35,000.00/sets 1-1 sets |

560*610mm Offline PCBA Flux Cleaning Machine 2 layers cleaning basket machine SMT PCBA cleaner machine

skype:sensenhenhao,whastapp/wechat:+8613424013606

off-line PCB/PCBA Cleaning Machine Description:

560*610mm Offline PCBA Flux Cleaning Machine 2 layers cleaning

basket machine is an off-line PCBA cleaning mahcine. It is a compact,

energy-saving and environmental protection machine.

SME-5600 is used to wash off flux residual, solder balls,

partichles on PCBA, such as: rosin flux, non-clean

flux,water-soluble flux.Mainly used in military,aviation, aerospace, medical, new energy,

automotive electronics industries, especially suitable for small

amount, multiple types PCBA cleaning.

SME-5600 advantages:

1. Throughly clean rosin flux, water-soluble flux , non-clean flux

,solder paste and other organic and inorganic contaminations on

PCBA.

2. 2-layers cleaning basket: 610mm(L) ×560mm(W) × 100mm(H) x2

layers.

3. All processes are visible through a large observation window.

4 .Easy operation interface, quick setting clean parameters.

Different passwords can be set.

5. Inner filter makes liquid used repeated.

6.Real-time measure DI water resistivity and monitoring cleaning effect. Resistivity range is 0~18 MΩ.

7. The remaining liquid in the pump and pipes are blown off by

compressed air and flow back to cleaning tank. This function saves

detergent up to 50%.

8. High standard cleanliness, ionic contamination completely meets

the requirement of IIPC-610D I class.

9. Totally SUS304 structure, solide, acid and alkali

corrision-proof

SME-5600 spec:

| ITEM | SPEC |

| Cleaning basket size | L610xW560xH100mmx 2layers |

| Diluent liquid tank capacity | 60L |

| Spray liquid tank capacity | 18L |

| Concentrate tank capacity | 30L |

| Cleaning time | 5~20min |

| Rinse time | 1~2 min/times |

| Rinse times | 1~10times |

| Dry time | 10~30min |

| Diluent liquid heat temp | room temp ~60ºC |

| PCB dry time | room temp~99ºC |

| Resistivity range | 0~18MΩ |

| Liquid filter | 0.2um |

| DI water filter | 0.2um |

| Air filter | 10um |

| Vent size | φ76XH50(mm) |

| Power supply | AC380, 3 Phases, 50/60Hz, 30KW |

| Air supply | 0.5Mpa, 400L/Min |

| Machine size | L1300xW1200x1850(mm) |

| Machine weight | 600KG |

Q1: What is the cycle time of SME-5600 batch cleaning machine?

A1: Total 30~45min. wash 10min+rinse 10min+dry 10~25min.

Q2: What liuqid can be used in SME-5600 to clean PCBA?

A2: It depends on electonical components and solder paste on your PCBA. Water-based PCBA cleaning liquid wash, DI water rinse.

Q3: Have many pcbas can SME-5600 clean in one cycle?

A3: L200*W100mm size PCBA for example, it can clean 30~40pcs.

Q4: Does the PCBAs need to bake after wash, rinse and dry process in the machine?

A4: Sure, PCBAs after clean need to put into electric oven and bake

for 2 hours at 100~110℃ or 4hours at 80~90℃to make the PCBA totally

dry.

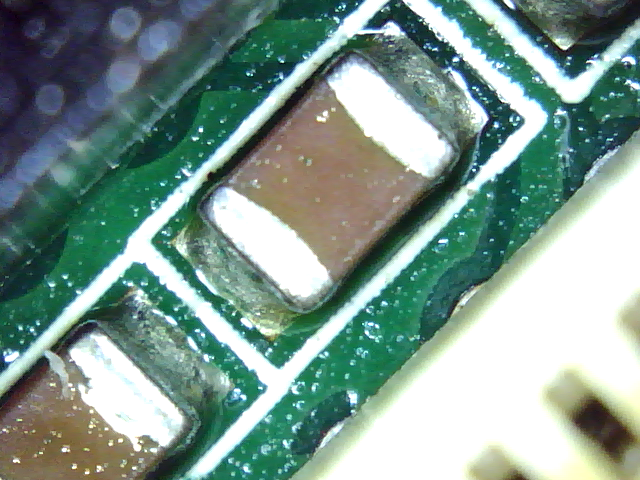

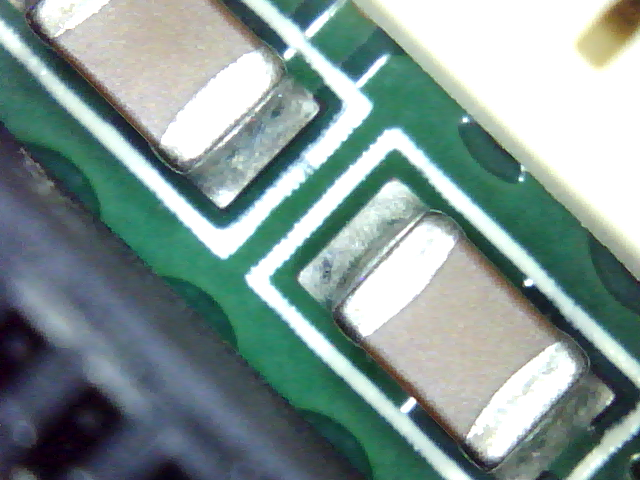

Comparison pictures before clean and after clean:

off-line PCB/PCBA Cleaning Machine picture show:

|