| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Inductor |

|---|---|

| Brand Name: | ZXY |

| Model Number: | T9*5*3-200uH |

| Certification: | RoHS,ISO9001-2001 |

| Place of Origin: | China,shenzhen city. |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T paypal xtransfer |

| Supply Ability: | 2000K-pcs/month |

| Delivery Time: | Stock Or 3 weeks |

| Packaging Details: | Carton |

| Keywords: | 200uH High Current Toroidal Power Inductor |

| Wire Material: | Copper Wire |

| Operating Temperature: | -40℃ to 125℃ |

| Tolerance: | 20% |

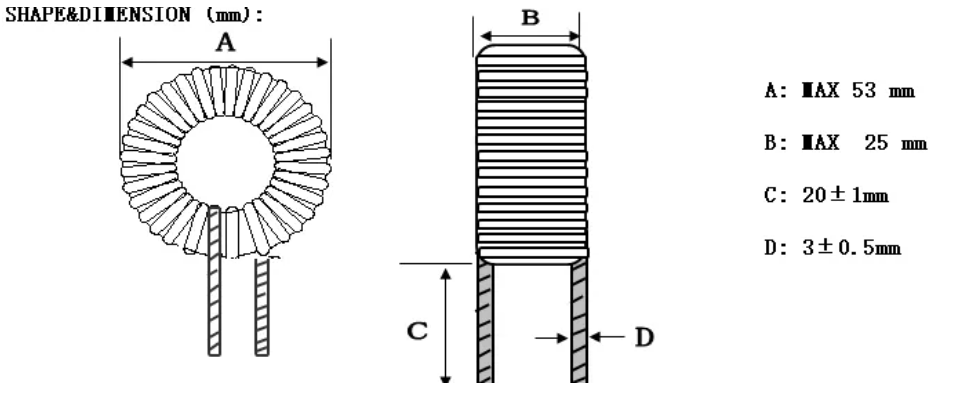

| Size: | T9*5*3 |

| Inductance: | Customized |

| Company Info. |

| Shenzhen Zhixiangyuan Electronics Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

The 200 uH high current ring power inductor, as a key component in the field of power electronics, achieves diverse and important functions with its unique performance and carefully selected materials, and is widely used in various circuits.

1.High inductance precision and stability: The nominal inductance is 200 μ H, providing stable and specific inductance values for the circuit. In circuits such as switch mode power supplies, this inductance can effectively store and release energy, ensuring efficient conversion and transmission of electrical energy. Moreover, under different working conditions, its inductance fluctuation is minimal, which can maintain stable circuit performance, such as ensuring normal operation of the circuit even under temperature and current changes.

2. Excellent high current carrying capacity: Designed to carry high

currents, it can easily handle currents of several amperes or even

tens of amperes. By adopting special winding design and

high-quality magnetic cores, inductance saturation is avoided when

the current is too high, ensuring stable operation in high load

circuits such as industrial motor drives and high-power switching

power supplies.

3. Low DC resistance (DCR): With low DC resistance characteristics,

it greatly reduces heat loss when current passes through and

improves inductance efficiency. Low DCR means that when

transmitting high currents, the loss of electrical energy converted

into heat energy is reduced, energy waste is reduced, the energy

efficiency of the entire circuit is improved, and the service life

of equipment is extended.

4. Excellent frequency response: Maintain good performance over a

wide frequency range, effectively handling both low and high

frequency signals. In high-frequency switching power supplies, it

can quickly respond to current changes, suppress high-frequency

noise, and ensure stable and pure output signals.

5. Low electromagnetic interference (EMI): The annular structure

concentrates magnetic flux, significantly reduces electromagnetic

leakage, and lowers electromagnetic interference to surrounding

circuits. At the same time, it also has strong resistance to

external electromagnetic interference, enhancing the

electromagnetic compatibility of the circuit, and is suitable for

equipment with strict electromagnetic environment requirements.

| Type: | 200uH High Current Toroidal Power Inductor |

| Application: | switch power supply |

| Tolerance: | 20% |

| Nature: | Inductor |

| Material: | Copper Wire |

| Inductance | Support custom |

| Operating Temperature: | -40℃ to 125℃ |

| size: | 4P*0.6mm |

| Certificate: | Lead free RoHS compliant |

1. Magnetic core material

--Ferrite core: a commonly used material with high magnetic

permeability, which can effectively concentrate magnetic fields and

improve inductance performance. It has low loss, especially

performs well at high frequencies, and can reduce energy loss and

heat generation. Suitable for scenarios with high requirements for

high-frequency performance, such as switching power supplies and

high-frequency circuits.

--Pomo alloy magnetic core: It has extremely high magnetic

permeability and can provide high inductance values under low

magnetic fields. Commonly used in circuits that require strict

inductance and precise control of magnetic fields, such as

precision measuring instruments and power circuits for high-end

audio equipment.

--Iron silicon aluminum magnetic core: It has good magnetic

permeability and saturation magnetic flux density, can withstand

large currents, and is not easily saturated under high currents. At

the same time, it has good temperature stability and low loss,

suitable for circuits with high current and high temperature

environments, such as industrial motor drives, automotive

electronics, and other fields.

2. Winding material: High purity copper wire is usually used

because of its high conductivity, which can reduce resistance and

minimize power loss when current passes through. For high current

applications, large-diameter wires or multi stranded wires are used

to increase the conductive area, reduce skin effect, and further

enhance the high current transmission capacity.

3. Insulation material: Insulation materials such as polyester

film, polyimide tape, etc. are used to isolate the winding from the

magnetic core and between each turn of the winding. These materials

have good electrical insulation performance and high temperature

resistance, ensuring stable operation of inductors in high current

and high voltage environments, and preventing faults such as short

circuits.

|