| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Solid State High Frequency Welder |

|---|---|

| Brand Name: | ZTZG |

| Model Number: | 800KW |

| Certification: | ISO9001/CE/SGS |

| Place of Origin: | China |

| MOQ: | 1Set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 200 sets/year |

| Delivery Time: | 120 Days |

| Packaging Details: | All mechanical equipment is nude packing and electrical parts are packed in wooden cases. |

| Welding Power: | 800KW |

| Pipe OD: | 89-325mm |

| Pipe Thickness: | 4.0-12.7mm |

| Working Speed: | 50m/min max |

| Control system: | By computer |

| Usage: | HF welding steel pipe lines |

| Advantage: | Efficient |

| Name: | Welding machine/ soldering equipment |

| Situation: | New |

| Marketing Type: | Ordinary product |

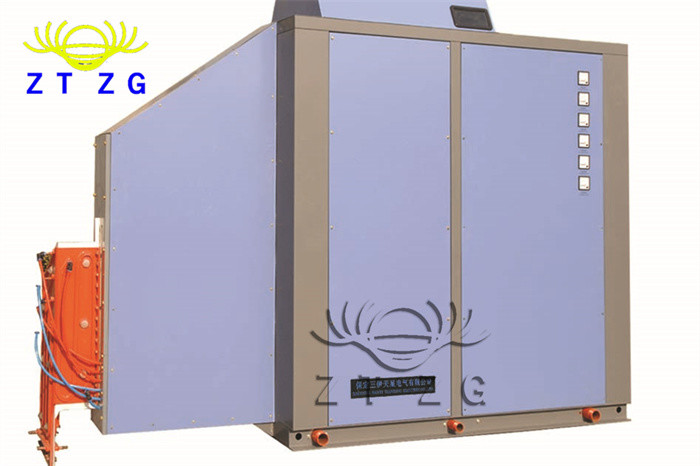

Soldering Machinery For Pipe Making Machine Solid State High Frequency Welder

Product Parameter

| Design parameters of the high - frequency welding machine | Rated output power: | 800kW |

| Rated DC voltage: | UdN= 450V | |

| Rated DC current: | IDN =2130A | |

| Efficiency: | η> 85% | |

| Composition of the solid - state high - frequency welding machine | Rectifier cabinet | 1 set |

| Inverter cabinet | 1 set | |

| Water ex-changer | 1 set | |

| Operation panel | 1 set | |

| Adjustment mechanism | 1 set | |

| Output confluence row | 1 set |

Structure

The whole set of solid state HF welder comprises of rectifying cabinet, inverter and output cabinet, connecting optical fiber, closed loop water cooling system, central operator console, mechanical adjustment device, etc.

Usage

It is used to be a high performance-heating unit controlled by computer for welding steel pipe.

Product Details

1.Switch Rectifying Cabinet

Install incoming disconnect switch ,incoming current meter, voltage meter(switchable)and incoming voltage indicating light.

Install 3-phase full-controllable thyristor rectifying bridge to achieve power regulation of H.F. welders.

Install flat wave reactor, flat wave capacitor and filter to increase flat wave coefficient.

2. Invert output cabinet

The invert part is considered of MOSFET single phase invert bridge in parallel style. Each bridge’s design power is 120 KW/60KW. We adopt building block mode to pile up power, it is very convenient to install and maintain because every single bridge board is designed as drawer structure consisted of slideway.

We adopt matching transformer to realize power combination, also we adopt sub-resonance, no-welding transformer output mode and make resonance directly by tank resonance capacitor(low voltage)and inductor to achieve steel pipe welding power transmission by output lead.

Use sealed box and install overhead air conditioning.

3. Central console

The console achieves remote control and power regulation of solid-state H.F. welder, installed with LCD; also it has indicators of armature voltage, field voltage on DC speed regulation cabinet and indicators of DC voltage, DC current on welder. Installation of power-speed closed loop control function is optional. The console has design difference according to different types and quantities of matching DC speed regulation cabinet.

4. Mechanical adjusting equipment

2-D adjustable bracket: for induction welding mode, applied with installation and adjustment of invert output cabinet, the inductor position can be adjusted manually.

3-D adjustable bracket: for induction/contract welding mode, applied with installation and adjustment of inverter output cabinet, the inductor position can be adjusted by electric or manual.

5. Circulation soft water cooling system (water-water cooler)

The water -water cooling system is composed of heat exchanger with the adoption of the special corrugated structure which makes the soft water form sharp turbulent flow in order to strengthen heat exchange. The system holds the advantage of compact design, small area occupation, convenient dismounting and high efficiency of heat exchange. Only with the ability of heat exchange but not cooling, it is necessary to use external circulation system to accomplish the heat exchange.

Model List

| Welder Model | Output Power (kW) | DC Power(kW) | Rating Current | Power Range |

| GGP60-0.5-H | 60 | 80 | 180A | 450~500kHz |

| GGP100-0.45-H | 100 | 120 | 270A | 400~450kHz |

| GGP150-0.4-H | 150 | 180 | 400A | 350~400kHz |

| GGP200-0.35-H | 200 | 240 | 530A | 300~350kHz |

| GGP250-0.35-H | 250 | 300 | 670A | 300~350kHz |

| GGP300-0.35-H | 300 | 360 | 800A | 300~350kHz |

| GGP400-0.3-H | 400 | 480 | 1070A | 200~300kHz |

| GGP500-0.3-H | 500 | 600 | 1330A | 200~300kHz |

| GGP600-0.3-H | 600 | 720 | 1600A | 200~300kHz |

| GGP700-0.25-H | 700 | 840 | 1870A | 150~250kHz |

| GGP800-0.25-H | 800 | 960 | 2130A | 150~250kHz |

| GGP1000-0.25-H | 1000 | 1200 | 2670A | 150~250kHz |

| GGP1200-0.25-H | 1200 | 1440 | 3200A | 150~250kHz |

|