| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tumbler Screening Machine |

|---|---|

| Brand Name: | AAREAL |

| Model Number: | AM |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 5 sets per month |

| Delivery Time: | 20~35 work days after order confirmed |

| Packaging Details: | Fumigation-free plywood wooden case for export |

| Screening Effect: | large screening capacity and high accuracy up to 90%~99.9% |

| Movement: | involute spiral motion |

| Optional Device: | pneumatic lifting devices, quick clamps etc. |

| Mesh Cleaning Device: | ultrasonic system, rolling brush, self-cleaning ball system, air brush etc. |

| Layers of Screen: | 1~5 layers of screen decks |

| Dia.: | 600mm, 1000mm, 1200mm, 1500mm, 1800mm, 2000mm etc. |

| Applications: | bakery yeast, mineral powders, plastic powders, plastic powder, glass beads, xylitol, citric acid, spherical mineral granules, calcium carbonate, nickel ore, food additives, food flour, micronised materials etc. |

| Other Names: | tumbler screening machine, tumbler screen, tumbler screener, tumbling screen |

| Company Info. |

| Xinxiang AAREAL Machine Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Plastic Powder Vibrating Screen Machine Ultrasonic Vibrating Sieve Separator

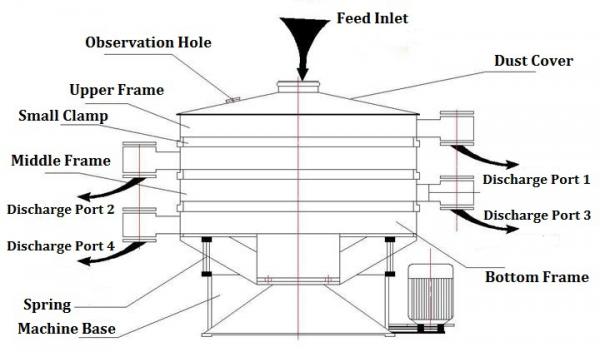

Overview of 0.025mm-1mm Sieve Accuracy Tumbler Screening Machines:

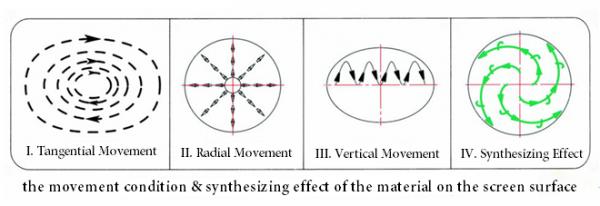

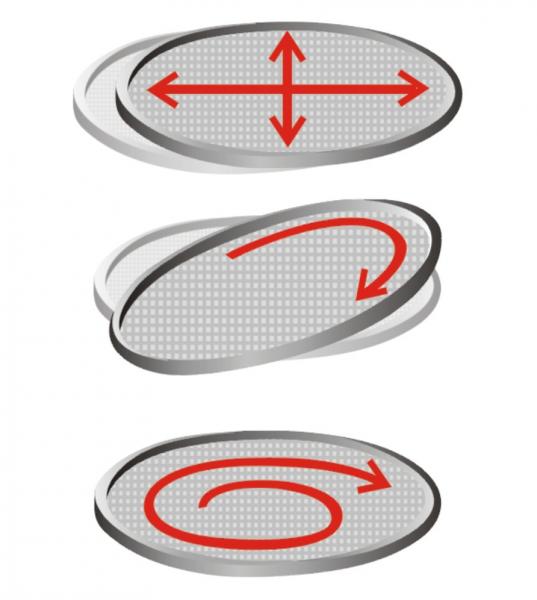

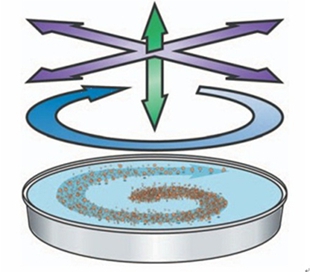

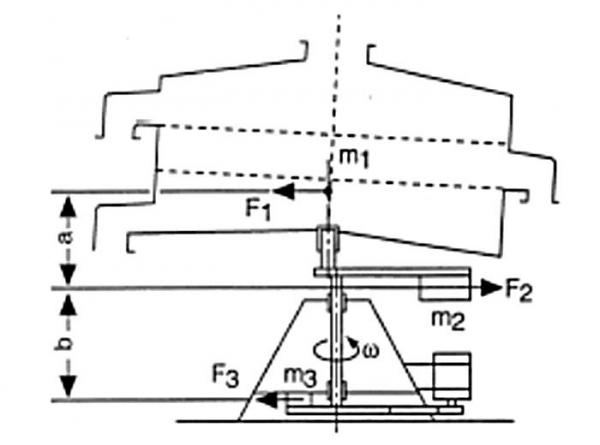

0.025mm-1mm Sieve Accuracy Tumbler Screening Machines is a low-frequency vibrating screen that imitates artificial vibration. The principle is that the instantaneous motion is the synthesis of the circular motion along the radial displacement and the displacement as the axis. Can regulate the vibrator eccentricity produce nonlinear three-dimensional movement, material also can produce the same approximation manual operation movement, so as to achieve the aim of screening, coupled with sieving attachment can get more ideal screening effect.

The tumbler vibrating screen Industrial circular vibrating screen filter sieve is a new and high-efficient sieving machine machine which is designed to meet the requirements of large output and high-density sieving. It make use of artificial sieving movement successfully (its sieving precision,sieve efficiency and sieve life is 5~10 times of common sieve machine), and suitable for all the fine, ultra-fine powder and special materials, particularly suitablefor materials which are difficult to deal with.

Our tumbler screen sieve sifter is widely used in many industries including chemical, food, spices, plastics, mining, medicine, wood and plywood, metallurgy, rubber, fodder, fertilizer, sugar, salt, renewable industries etc.

This large capacity tumbler screen uses a operating principle of slow acceleration and a longer residence time on the mesh surface area, the action is extremely gentle on the product being processed and is more suited to handle fragile material.

Application of 0.025mm-1mm Sieve Accuracy Tumbler Screening Machines:

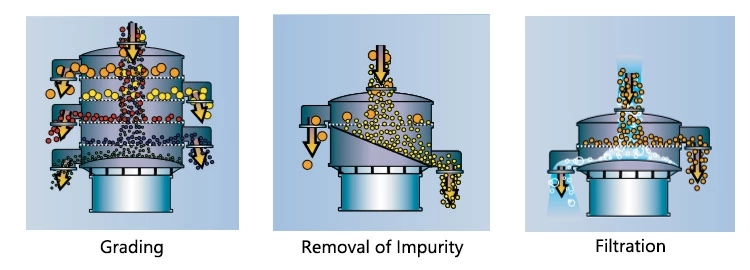

Tumbler Sievie shaker is used at powder lines, mill discharge or storage tank discharge for separation, purification, grading, refining, dedusting, filtration.

1. Metallurgy, Mine industry: aluminum powered, copper powder, ore alloy powder, welding rod powder etc.3. Waste treatment: disposed oil, disposed water, disposed dye waste water, active carbon etc.

4. Food industry: sugar powder, starch, salt, rice noodle, milk powder, egg powder,

sauce etc.

5. Chemical industry: resin, pigment, cosmetic, coatings, Chinese medicine powder etc.

Important Information About 0.025mm-1mm Sieve Accuracy Tumbler Screening Machines:

| Motion | involute spiral motion |

| Screening Accuracy | upto 90%~99.9% |

| Mesh Cleaning Method | bouncing ball cleaning, ultrasonic cleaning, brush cleaning, air cleaning, ultrasonic air cleaning, air brush cleaning |

| Screen Structure | whole adhesive screen, or splicing segmented screen etc. |

| Layers of Screen | 1~5 layers of screen |

| Dia. | 600mm, 1000mm, 1200mm, 1400mm, 1500mm, 1600mm, 1800mm, 2000mm, 2100mm, 2300mm, 2600mm etc. |

| Advantages | soft rock screening will not destroy the particles original structure of the material and not easy to produce static electricity |

| Optional | quick clamps, pneumatic lifting devices etc. |

| Motor | ABB, Siemens etc. |

| Application | can be used for materials that is flammable, explosive and easy to generate static |

Working Principle of 0.025mm-1mm Sieve Accuracy Tumbler Screening Machines:

The tumbler screen machine is an artificial imitation of shaking low frequency vibration sieve, working principle is synthesis of transient motion displacement and this displacement in the radial direction of the axis of circular motion (helical motion), can adjust the eccentricity nonlinear three-dimensional motion of the exciter, the material also produces same motion approximation manual jobs, so as to achieve the purpose of screening, combined with sieving attachment can get more ideal screening effect. Suitable for circular, cylindrical, sheet, and even regular shapes easy to block network and require sophisticated screening materials.

Technical Parameters of 0.025mm-1mm Sieve Accuracy Tumbler Screening Machines:

| Model | AM600 | AM1000 | AM1200 | AM1500 | AM1800 | AM2000 | AM2300 | AM2600 | AM2900 |

| Area of Screen(㎡) | 0.28 | 0.72 | 1.10 | 1.80 | 2.30 | 2.60 | 3.90 | 5.30 | 6.40 |

| Number of Screen Deck | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 | 1-5 |

| Power(kW) | 0.25 | 1.5 | 1.5 | 2.2 | 4.0 | 4.0 | 4.0 | 5.5 | 5.5 |

| Cleaning System | Options: Rubber Balls, Rotating Brush, Compress Air, Ultrasonic and Scrapper | ||||||||

Features of 0.025mm-1mm Sieve Accuracy Tumbler Screening Machines:

1. Many options for cleaning system: Rubber Balls, Rotating Brush, Compress Air, Ultrasonic and Scrapper, can effectively maintain sieving.

Pneumatic Lifting Device BALANCE IS IMPORTANT !!

Contact: Ms. Magie

E-mail: sale@aarealmachine.com

magiecn@gmail.com

WhatsApp/WeChat: 0086-15637361027

Website: https://www.aarealmachine.com

|