| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Transformer Oil Purifier Machine |

|---|---|

| Brand Name: | REXON |

| Model Number: | ZYD-100(6000LPH) |

| Certification: | CE, ISO, SGS, CCC |

| Place of Origin: | Chongqing, China |

| MOQ: | 1 Set |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 500Sets per Month |

| Delivery Time: | 3~10 working days basd on exact model |

| Packaging Details: | Standard Wooden Cases for Export |

| Function: | Transformer Oil Filtering |

| Process Capacity: | 6000LPH |

| Power Supply: | 380V, 3Phase, 50HZ Or As Required |

| Color: | Green, Blue, Grey, White, Yellow ETC. |

| More Advantages: | Weather Proof | Dust Proof | Enclosed Type |

| Work Principle 01: | Automatic Foaming Elimination |

| Work Principle 02: | Vacuum Oil Dehydration |

| Work Principle 03: | Multi-Stage Oil Filtering |

Dust-proof & PLC Type Double Stage High Vacuum Transformer Oil Filtration Machine

6000Liters/Hour

Why Need Transformer Oil Purifier:

There are contaminants in transformer oil as following:

1.Solid particles like rust scales, dust and fibres

2.Generation of carbon particles due to ageing of switchgear

3.Oil absorbs moisture resulting in free and dissolved water

4.Absorption of air

5.Aging fluids produce absorbed gases, causing equipment failure

and arc suppression in swithgear

6.Sludge formation

7.Increase in acidity level

8.Chemical products are caused by oxidation, as well as cross

contamination of other products.

Rexon Transformer Oil Purifier Brief Introduction

Machine Condition: New

Treatment Capacity: 6000 L/H

Working Pressure: ≤0.4 Mpa

Place of Origin: Chongqing, China (Mainland)

Brand Name: REXON OIL PURIFICATION

Model Number: ZYD-100

Application: Transformer Oil

Power data: 380V 50HZ/3 Phase Or As Required

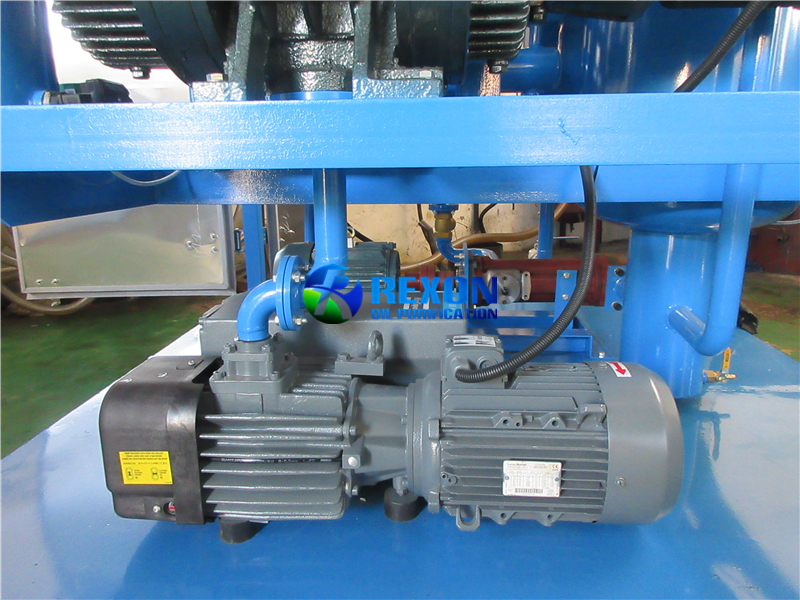

Vacuum Dehydration(Degas) system

Our Double-horizontal vacuum evaporation vessels can enlarge

evaporation area efficiently. The heater, being places in the

vacuum vessels, becomes an evaporator. Thus the evaporation areas

of Double-horizontal vacuum vessels are three times more than of

the common vacuum vessel. This innovation can dehydrate and degas

effectively and separately. This optimal structure of the

dehydration (degas) system enlarge the surface area of oil exposed

to the vacuum system and extends the flowing distance of the oil in

the vacuum system. Thus there has sufficient time to remove the

moisture and gas from the oil by vaporization.

Technology and benefits of the model:

1: It is for treating a range of insulating oil, including

transformer oil, mutual inductor oil, change oil.

2: It is extensively applied in large scale manufacturing factory,

energy station and other related industrial fields which will use

transformers, specifically for more than 110 KV transformers.

3: Double point vacuum system, adopt international remarkable

duplex stereo-evaparation technology and british G technology to

eliminate the trace water in insulation essential oil and recover

its breakdown voltage greatly.

4: Adopt Germany's 3 UG phase replay, will make the machine

functioning efficaciously and safely at any situations, such as

energy off, lack of phase, wrong phase position, etc.

5: Equipped with remarkable dielectric condensation devices for

greatly prolong the essential oil purifier provider life.

6: A trinity of interlocked preventive unit is applied for avoid

the machine becoming damanged from any incident automatically.

7: It also can be used becoming a separate vacuum method for

dehydrating essential oil only, don't should operate all procedure

and can save time and consumption for different ask on essential

oil filtration.

8: it may purpose onsite using the transformer operating together.

9: A PLC method can be attached as per customer's requirement.

10: it may be moved easily with equipped steel wheels, it also can

be created for different structure of completely enclosed type and

completely enclosed trailer type to the objective of ourdoor use

and indoor use.

11. a range of coloring of the model can be produced just as

customer's favor.

Plants are available in different types of constructions such as

open & enclosed models, stationery, portable & mobile models, with

single & double stage degassing / dehydration system.

Technical Parameters:

| Parameters | Unit | ZYD-30 | ZYD-50 | ZYD-100 | ZYD-150 | ZYD-200 | ZYD-250 | ZYD-300 | |

| Flow Rate | L/H | 1800 | 3000 | 6000 | 9000 | 12000 | 15000 | 18000 | |

| Working Vacuum | Mpa | -0.08 ~-0.099 | |||||||

| Working Pressure | Mpa | ≤ 0.3 | |||||||

| Temp Range | ℃ | 20 ~80 | |||||||

| Power Supply | 380V, 50Hz, 3Phase( As per required) | ||||||||

| Working Noise | Db | 60 - 80 (Depended on the configuation) | |||||||

| Heating Power | KW | 30 | 60 | 90 | 135 | 150 | 165 | 180 | |

| Total Power | KW | 35 | 67.5 | 101.5 | 149 | 164 | 198 | ||

| Inlet/Outlet Diam | MM | 25 | 32 | 42 | 50 | 50 | 60 | 60 | |

| Weight | KG | 450 | 550 | 750 | 950 | 1200 | 1850 | 2000 | |

| Size | Length | MM | 1450 | 1450 | 1750 | 1850 | 1950 | 2050 | 2150 |

| Width | MM | 950 | 1000 | 1250 | 1300 | 1350 | 1400 | 1450 | |

| Height | MM | 1700 | 1750 | 1950 | 2000 | 2050 | 2100 | 2150 | |

| AFTER TREATMENT | |||||||||

| Dielectric Strength | KV | ≥ 75-85 | |||||||

| Water Content | PPM | ≤ 3 | |||||||

| Gas Content | % | ≤ 0.1 | |||||||

| Particle Size | μ | ≤ 3 | |||||||

| Cleanliness ≤NAS 1638 Grade 5 | |||||||||

Advantages:

Weather Proof Type Transformer Oil Purifier High Capacity Vacuum

Dielectric Oil Purifier Machine 18000Liters/Hour, Dust Proof Type

for Oustide Use, it can protect the machine not to be damaged by

raining weather, or in other bad circumstance use. So you can take

use of the machine in any weather and many circumstances for any

on-site oil filtration project.

|