| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Conical Screw Blender |

|---|---|

| Brand Name: | Shengli |

| Model Number: | DSH |

| Certification: | CE and ISO |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 sets per month |

| Delivery Time: | 1 MONTH |

| Packaging Details: | NAKED OR WOODEN CASE |

| Voltage: | 380v, 50hz, 3phase |

| Applicable Industries: | Manufacturing Plant |

| warranty: | one year |

| Capabilities: | heating and cooling |

| Speed: | 2rpm to 100rpm |

| Power: | 3kw to 30kw |

Double Screw Vertical Conical Screw Blender with Non-residual Discharge for Detergent Powder Mixing

official website:www.1985shengli.com

Introduction

Conical mixer is widely used in chemical, dyestuff,battery and rare earth line.

Product features

1. full discharge and no leftover.

2. Gentle mixing no damage to fragile material.

3. Low-energy,more adaptable to chemical&physical reaction.

Working principles

Double screw conical mixer rotated around its axes by right of two

internal asymmetric spirals which is installed on the cantilever.

Mean while, the rotational force from the cantilever drive two spiral doing revolution around conical chamber axle wire

Double screw conical mixer has 4 direction forces

1.Two inner asymmetric spiral upgrade materials by rotation

2. Tumbler low-speed rotation makes material circle motion

3. Spiral rotation and revolution make materials absorbed while

diffuse to circle direction

4. T wo flow materials upward then down to center which come into

being a downward material flow This way can full the bottom gap and

form a convective circulation

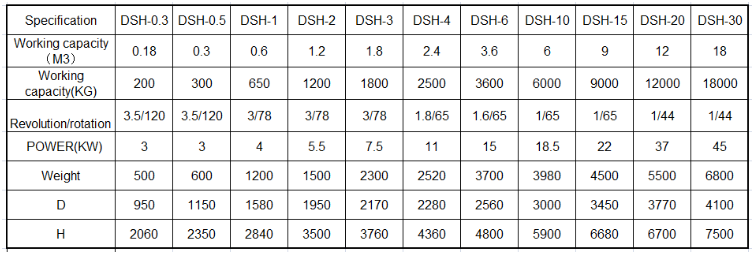

Data

Configuration

1.Reliable driven unit

The driven unit and power is varied according to different raw

material, starting method, and processing.

Double screw conical mixer is equipped with appropriative double

output reducer, which combines pinwheel, gear and warm and gear.

2.Excellent discharging unit

Spherical valve or plum-blossom dislocation valve is matched to the double screw conical mixer.

The surface of the valve match the track of the bottom of screw, to reduce the mixing dead zone to the maximum,

and to make the largest discharging area, so as to make sure no leftover.

Spherical valve has excellent sealing effect to powder, liquid and even in the negative pressure state.

Plum-blossom dislocation valve is easy to operate and control the discharging speed

3.Powerful auxiliary components

Equipped with circulation medium of jacket, the double screw

conical mixer can realize the temperature control in mixing

process.

In the mixer barrel, the part contact with material can coat some

antiriot, anti-caking and metal isolation material according to

different ingredient.

In some severe wear conditions, the screw surface can be overlaid

by some wear proof alloy.

If a small quantity of liquid is required during mixing, spraying

or atomizing unit is necessary in order to mix the liquid evenly

with the main ingredient.

The liquid-adding system is basically composed by the three parts: pressure source, liquid storage pot and spraying nozzles

Simple Production line & parameter:

Configuration 1: conical mixer with manually feeding

Configuration 2: conical mixer, manually feeding device with dust

collector

Configuration 3: conical mixer with vacuum feeder

Configuration 4: conical mixer with crane

Configuration 5: conical mixer with screw conveyor

Configuration 6: conical mixer with bucket elevator

Configuration 7: simple production line with conical mixer, vacuum

feeder, storage tank and auto-packing machine.

Configuration 8: simple production line with conical mixer,

manually feeding, screw conveyor to storage tank and auto-packing

|