| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cable Tray Roll Forming Machine |

|---|---|

| Brand Name: | LBM |

| Model Number: | LBM-CTM-004 |

| Certification: | ISO 9001: 2008 |

| Place of Origin: | Wuxi City, Jiangsu Province, China |

| MOQ: | 1 Set |

| Price: | USD 75000~120000 Per Set |

| Supply Ability: | 20 Sets per Month |

| Delivery Time: | 35 days |

| Packaging Details: | Export Sea Worthy Packing with each machine tied and protected in the container |

| Material: | GL, SS, and AL coil |

| Types: | Trough, Ladder, Trays |

| Width: | 100~600mm |

| Height: | 50~200mm |

| Thickness: | 0.6~2.0mm |

| Forming Speed: | 0~10m/min |

| Power: | 4*4Kw + 7.5Kw + 9 Kw |

| Total Weight: | Approx. 30 Tons |

Custom Full Automatic Cable Tray Roll Forming Machine Mitsubishi brand PLC control system

1. Description of Cable Tray Roll Forming Machine

All roll mills have one purpose, and that is to take a coil of flat metal and bend it progressively through a series of rolls to make a “section” or channel, usually nicknamed after what letter they resemble.

For instance, a U channel looks like a residential gutter. A Z-section looks like a letter Z, with two bends in opposing directions, and the center bit stays more or less alone.

A cable tray roll forming machine works just like any other forming machine. On a mill fitted with rolls designed to make that particular section, usually a U or C section, and a pre-punching, fitted with a die that puts holes into the part, usually, before it is rolled and bent into the desired shape. A second press at the end of the line cuts the parts to the desired length.

2. Main Technical Parameters

| No. | Item | Description |

| 1 | Material | GL, SS, and AL coil |

| 2 | Cable tray type | Trough type, Ladder type, Trays type |

| 3 | Cable tray width | 100~600mm |

| 4 | Cable tray height | 50~200mm |

| 5 | Thickness | 0.6~2.0mm (for GI sheet and coil) |

| 6 | Feeding width | 200~1050mm |

| 7 | Strength | 235 Mpa |

| 8 | Speed | 0~10m/min |

| 9 | Size tolerance | 1mm |

| 10 | Size changing method | Automatic |

| 11 | Power | 4*4Kw + 7.5Kw + 9 Kw |

| 12 | Roller material | No.45 Steel, coated with hard chrome |

| 13 | Cutter blade material | Cr12 steel, quenched treatment |

| 14 | Dimension | 200000*2500*1500mm (L* W*H) |

| 15 | Total Weight | Approx. 30 Tons |

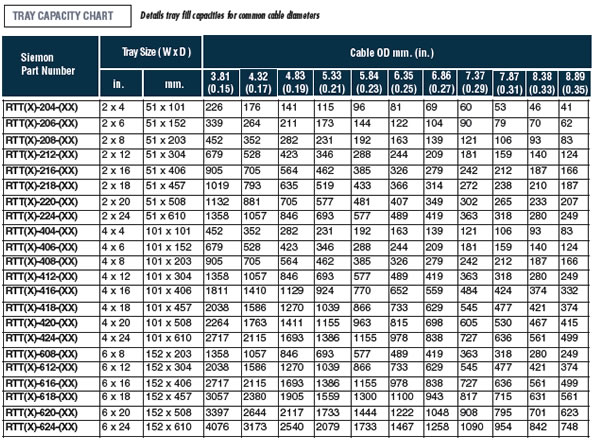

3. Cable Tray Size

4. After-sales Service

A. Foreign debugging

If you need, we will arrange for our professional engineers to help you install and debug the machines well. Buyer should pay $100 per day

B. Guarantee period

The warranty will be maintenance, maintain in the guarantee period of 18 months starting from delivery. Because of the quality of equipment during the guarantee period, we will provide the parts free of charges, which is in the conditions of correct operation. (Natural disasters or factors which can’t force by human are excluded).

C. Training

During installation and adjustment of the equipment, our engineers shall provide the training to

the buyer’s personnel request to operate and maintain the equipment. Including foundation construction, electrical works, hydraulic oil, safe operation and non-standard safety items, testing material and etc.

D. Lifetime services

Life time services to every customer.

|