| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Customized Wire Drawing Machine |

|---|---|

| Brand Name: | HXE |

| Model Number: | 24DTA |

| Certification: | ISO/SGS |

| Place of Origin: | China(Mainland) |

| MOQ: | 1 set |

| Supply Ability: | 30 sets per year |

| Delivery Time: | 45-60 work days |

| Packaging Details: | Packed with plastic film, U-steel under the machine.20GP Container |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Usage: | Drawing and annealing |

| Inlet diameter: | 0.8mm-1.6mm |

| Outlet diameter: | 0.1mm-0.6mm |

| Main motor: | AC 3 Phase 18.5KW |

| Annealer motor: | AC 3 Phase 3.7KW |

| Take up motor: | AC 3 Phase 3.7KW |

| Product name: | Non standard wire drawing machine |

| After-sale service: | Engineer available to overseas |

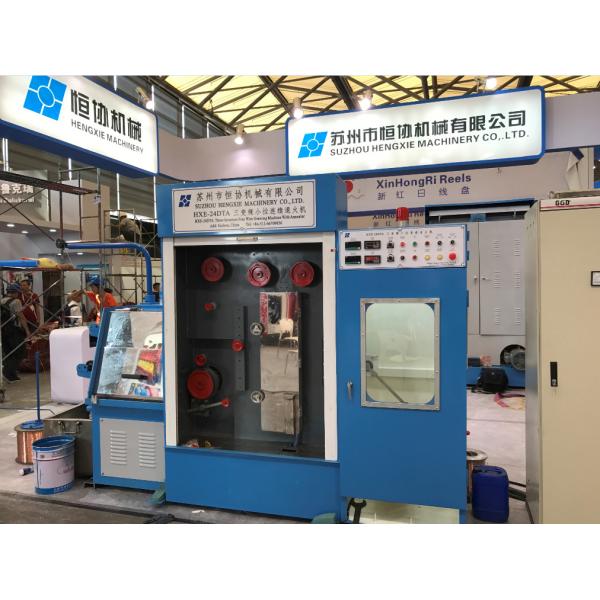

HXE-24DTA Copper fine wire drawing machine with annealer

I. Application

HXE-24DWT Copper fine wire drawing machine with annealer is used to draw and anneal single bare copper wire from 0.8mm-1.6mm to 0.1mm-0.6mm.

II. Components

| Name | Quantity |

| 1. Pay-off stands | 1 set |

| 2. HXE-24DTA main drawing machine | 1 set |

| 3. Electrical cabinet | 1 set |

| 4. Steam generator | Not available |

| 5. Lubrication tank and Pump | 1 set |

| 6. Bobbin Loading&Unloading trolley | 1 set |

| 7. Spare part for one year | 1 set |

| 8. Others |

III. Main Technical parameters

1. Usage: Copper wire drawing and annealing

2. Inlet diameter: 0.8mm-1.6mm

3. Outlet diameter: 0.1mm-0.6mm

4. Max. mechanical speed: 2000m/min

5. Dies: 22 dies

6. Slip ratio: 15%, Finished capstan slip ratio: 8%

7. Main motor: AC 3 Phase 18.5KW, Inverter control

8. Annealer motor: AC 3 Phase 3.7KW, Inverter control

9. Take up motor: AC 3 Phase 3.7KW, Inverter control

10. Power transmission: Timing belts+Triangle belts+Flat belts

11. Take up capacity: 50kg for diameter 300mm iron spool

(Customize)

12. Spool size: Diameter 300mm/Max (Customize), 250mm-127mm spooler

is totally ok

13. Capstans: Ceramic plasma, Drawing capstan 242mm, Final capstan

207mm

14. Capstan lubrication: Water pipe spray

15. Traversing: 110W synchronous motor,transmission by flat belts.

16. Brake: 20KG-M Electromagnetic brake

17. Air pressure: 4-6kg/cm2

18. Annealing pulley: Diameter 120mm

19. Annealing volt: DC60V

20. Annealing current: DC800A

21. Annealing motor power: 48KVA

22. Tension control: Annealer & Spooler Tension control by Swing

arms, Air pressure auto adjust.

23. Machine dimension(L*W*H): 3500mm*1600mm*2200mm, Machine

weight:3200kg

24. Power source: 415V, 50Hz(Customized)

IV. Machine structure

Annealing method is DC Three section annealing, there are three contact capstans, as Pre-Heating, Annealing and Drying. For drawing machine part, there is belts that connection from the Fix-speed capstan to the Annealer machine to achieve the transmission, as keep same speed.

Connect the Up capstan and Down capstan with Positive and Negative power, to make the wire in a short circuit, to achieve the heating.

There is annealing plate to auto track and adjust the speed and annealing voltage.

To achieve fast coolant to make the wire soft(Annealing), the Down capstan is immersed into the coolant water(There is a water tank in the bottom of the Annealer machine), coolant water is 0.5% emulsion. With the Pump to pump the coolant water through all pipes and valves, half sealed annealing door. Adjust the valves to adjust the coolant water in certain height.

To make sure the wire no oxidation, in the annealing protection pipe has steam (Buyer self will prepare Steam generator).

In the drying section, has a blowing device (Require two Tungsten dies, Buyer self prepare), by compressed air (Buyer self prepare Air compressor) to blow the water on the surface of the wire.

Lubrication oil concentration of mix with water 2-3%.

V. Advantage and after-sale service

A: Advantage

(1). HENGXIE has some world famous parts suppliers, has special

lubrication system for the gears and bearing.

(2). Body and other key components and parts are produced by our

own factory , quality is reliable.

(3). DC. three-section annealing

(4). Our company’s developing process in more than 10 years.

B: After-self service

Our company for all machine product, since the shipment date, our

company free after sale maintenance service guarantee period is:

(1) 1 year for mechanical part.

(2) 6 month for electrical part.

Under these situation mentioned, the Seller will not take

responsibility, but if the Buyer agree, will charge fees

accordingly to repair the machine.

A. Due to wrong operation while shipping.

B. Due to Buyer`s wrong preparation that may cause damage to the

machine.

C. Due to Buyer`s wrong operation that may cause damage to the

machine.

D. Not in the consuming part list.

E. After agreement are made for the shipping, for any damage, Buyer

should inform Seller in letter form to repair in seven days, If

beyond the dare, Seller shall take no responsibility.

F. For any other failures due to acts of God (such as lightning,

typhoon, earthquake, riots, war, fire or flood) and other factors

that will cause damage, Seller shall take no responsibility.

G. Seller guarantee provide long term support regarding the parts

and teach. After warranty, will charge accordingly.

|