Why choose us:

- During the production of a rubber,plastic,polyurethane, or

rubber-metal combination production, layers or flaps of unwanted

material are created because material overflows from within the

mould cavities.

- This excess material is commonly known as “flash””burrs”;The excess

material(or flash) almost always needs to be effectively removed

before the product is deemed to be used for purpose;

- Many factories still use manual methods to deflash their products,

which is low efficiency, time-consuming, labour intensive or even

dangerous, and are not always effective in producing a high quality

finished part with all the flash sufficiently removed.

- Considering about the keep increasing labor cost and quality

products required by users; Manufactures even work hard, will lose

the competitiveness and market, traditional manual methods will be

out of use sooner or later;

- Our fully automatic vacuum trimming machine is simple and automated

line for trimming edges of all kinds of rubber, plastic & sorts of

soft half-hard subjects/parts, U packing, special for oil seals and

diaphragm of brake;

- Our Angle Trimmer machines are available as a one, two or three

head model.

- These options have been specifically designed to produce a high

quality finished product and to significantly increase processors’

operational productivity, and reduce labour costs as well;

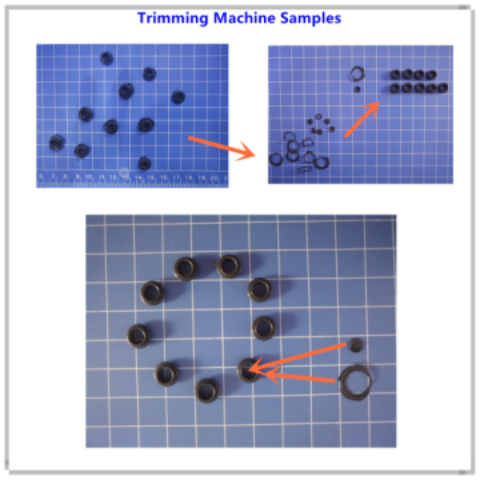

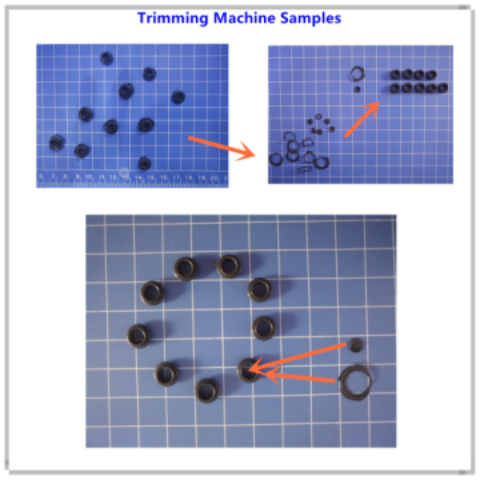

Above photo is the typical use of trimming for 2 cutters;

Applications& Advantages :

- Ideal for single size items with large Amount; Auto feeding and

auto trimming;

- A safe, affordable and automated process;

- Suitable for the effective trimming of small to medium size rubber

parts;

- Able to cut the bevel angle of plain face, inner & outer bevel

angle at a time;

- Quick, simple and effective, one worker can operate 3~4 machines at

a time to reduce the manufacture cost;

- Ideal for use in the automotive, oil and gas, aerospace, medical

,electronic and general rubber parts;

Features:

- 1.With the design of vacuum adsorption and blowing, making it easy

to realize the automated installation of product onto

spindle/mandrel by the mechanical arm, greatly improving

efficiency.

- 2.PLC controller, automatic feeding and unloading. No need to

change clamping apparatus for the next cutting job .

- 3.Use the friendly HMI, all parameters can be seen clearly and it

is quite easy to operator.

- 4.All electrical components and pneumatic components adopt import

and domestic well-known brand products, assuring the stability and

reliability of long-term usage;

Why should I use the Fully Automated trimming machines :

The fully automated trimming machine offers a quick and cost

effective solution to cut angles for small & medium size Moulded

rubber part;

- It is able to do this in short time without involving new operator;

- It offers considerable advantages to processors over manual or

half-auto machining method of trimming ;

- No experience required to operator;

- Reduction in production time;

- Reduction in labor cost;

- Enhanced part quality;

- Improved operator safety;

- Fully Automated production;

When should I use the Fully Automated trimming machines?

- The fully automated trimming machine offers a quick and fully

automatic process to cut angles for small & medium size Moulded

rubber part;

- When get the chance of the hot products in market or customers

newly requirements for some unique size product with large

Quantity;

- A fully automatic machine will be a better optional;

How does the Fully the Automated trimming machine work ?

- The process is quick ,requiring minimal operator skills;

- 1. A size fitted vibrator is as the material storage and realizes

automatic feeding.

- 2. A mechanical arm to pick the piece of product and install onto

spindle and pick it away to conveyor upon completion .

- 3. The strong vacuum system to absorb the piece of product closely

to spindle, Meanwhile the cutters to do the cutting job with required cutting

performance;

- 4. Parameters setting through the PLC touch screen, which is simple

operation and easy adjustment.

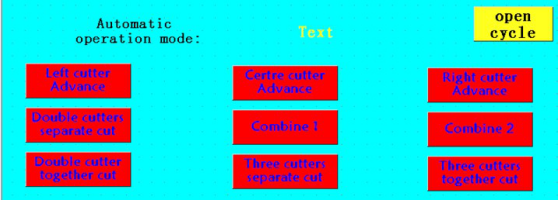

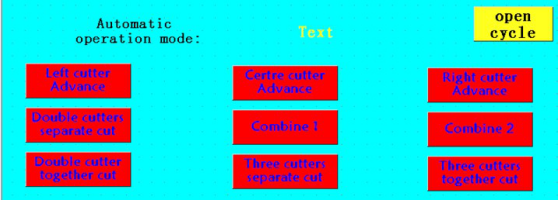

- 5. Heads can be individually cycled to move, extend stroke, rotate

spindle, cut, retract and stop in a manual or single cycle mode.

The machine has several modes of automatic cycling. Multiple heads

can be set to cut at the same time, or each head can run by itself.

All automatic cycle starts are actuated by ergonomic touch button.

Technical Parameters :

| Model No.: | TCY-200-N |

| Cutting cycle cuts / minute* max | 15~25 Times/Min |

| Working Rotate Speed | 0~3000r/min |

| Cutting Diameter | Φ6mm~Φ60mm (If special size, contact us for further discussion) |

| Compressed Air Consumption | 20L/min |

| Atmospheric Pressure | 0.5MPa~0.8MPa |

| Working Vacuum Degree | 760mmHG |

| Power Source | AC220V±5% or AC380±5% 50/60HZ |

| Total Power | 2 KW |

| Device Weight | ≈460Kg |

| Device Size (L×W ×H) | 1550mm×620mm×1380mm |

Order Options :

Nos of head;

Capaciy of vibrator;

Size of trimming range;

Color of Machine;

Tags:

Trimmers; Trimming Machines; Angle Trimmers; Rubber Trimming

Machine;

Mandrel Cutting Machine;Slicing Cutting Machine;Precision machines

for cutting off rings and slices;Oil filter sealing gasket making

machine;

Slice machine; Slicer;Circular knife cutting machines for cutting

gaskets;Rubber gasket cutting machine;Gasket making mahcine;

Rotary style gasket cutter;Rotary cutting machine; Rubber slitting

machine; Machines for hose and tube processing;

Cutting machine for hoses and tube processing; Machine for rubber

and plastic processing; Cutting machine for gaskets and o-rings;

For more details, please contact us freely !!!

CONTACT INFOS

Person: Susanna

INTER-CHINA RUBBER MACHINERY CO., LTD.

www.rubbermachinery-china.com

Mob:+0086-13179487165

SKYPE: rubbercutting

Email : info@rubbermachinery-china.com