| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Electronic Printed Circuit Board |

|---|---|

| Brand Name: | KAZ |

| Model Number: | KAZA-B-045 |

| Certification: | UL&ROHS |

| Place of Origin: | China |

| MOQ: | 1 Unit |

| Price: | 0.1-20 USD / Unit |

| Payment Terms: | T/T, Western Union, MoneyGram, L/C, D/A |

| Supply Ability: | 2000 m2 / Month |

| Delivery Time: | 5-30 days |

| Packaging Details: | vacuum package |

| Layer Count: | 2 ` 30 Layers |

| Max Board Size: | 600 mm x 1200 mm |

| Base Material for PCB: | FR4, CEM-1, TACONIC, Aluminium, High Tg Material, High Frequence ROGERS ,TEFLON, ARLON, Halogen-free Material |

| Rang of Finish Baords Thickness: | 0.21-7.0mm |

| Minimum Line Width: | 3mil (0.075mm) |

| Minimum Line Space: | 3mil (0.075mm) |

| Minimum Hole Diameter: | 0.10 mm |

| Finishing Treatment: | HASL (Tin-Lead Free), ENIG(Immersion Gold), Immersion Silver , Gold Plating (Flash Gold), OSP, etc. |

| Thickness Of Copper: | 0.5-14oz (18-490um) |

| E-Testing: | 100% E-Testing (High Voltage Testing); Flying Probe Testing |

| Company Info. |

| ShenZhen KaiZhuo Electronic Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

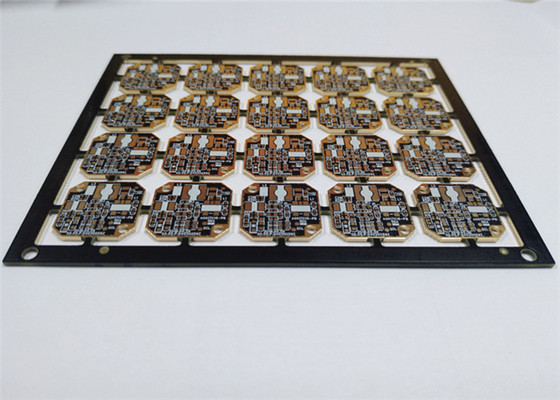

Gold Plating Surface Finishing Electronic Board Assembly Multilayer Circuit Board

Features of Circuit Board

1. One Stop OEM Service, Made in Shenzhen of China

2. Manufactured by Gerber File and BOM List from Customer

3. FR4 Material, Meet 94V0 standard

4. SMT, DIP technology suport

5. Lead Free HASL, Environmental Protection

6. UL, CE, ROHS Compliant

7. Shipping By DHL,UPS, TNT, EMS or Customer requirement

Circuit board Technical capability

| SMT | Position accuracy:20 um |

| Components size:0.4×0.2mm(01005) —130×79mm,Flip-CHIP,QFP,BGA,POP | |

| Max. component height::25mm | |

| Max. PCB size:680×500mm | |

| Min. PCB size:no limited | |

| PCB thickness:0.3 to 6mm | |

| PCB weight:3KG | |

| Wave-Solder | Max. PCB width:450mm |

| Min. PCB width: no limited | |

| Component height:Top 120mm/Bot 15mm | |

| Sweat-Solder | Metal type :part, whole, inlay, sidestep |

| Metal material:Copper , Aluminum | |

| Surface Finish:plating Au, plating sliver , plating Sn | |

| Air bladder rate:less than20% | |

| Press-fit | Press range:0-50KN |

| Max. PCB size:800X600mm | |

| Testing | ICT,Probe flying,burn-in,function test,temperature cycling |

Printed circuit boards (PCBs) are the basic components of electronic equipment and are the physical foundation that connects and supports various electronic components. It plays a vital role in the functionality and reliability of electronic systems.

Key aspects of electronic printed circuit boards include:

Layers and composition:

PCBs are typically made up of multiple layers, with the most common

being a 2- or 4-layer design.

These layers are made of copper serving as conductive paths and a

non-conductive substrate such as fiberglass (FR-4) or other

specialty materials.

Other layers may include power and ground planes for power

distribution and noise reduction.

Interconnects and Traces:

The copper layer is etched to form conductive traces that serve as

pathways for electrical signals and power.

Vias are plated-through holes that connect traces between different

layers, enabling multi-layer interconnections.

Trace width, spacing, and routing patterns are designed to optimize

signal integrity, impedance, and overall electrical performance.

Electronic component:

Electronic components, such as integrated circuits, resistors,

capacitors, and connectors, are mounted and soldered to the PCB.

The placement and routing of these components is critical to

ensuring optimal performance, cooling, and overall system

functionality.

PCB manufacturing technology:

PCB manufacturing processes typically involve steps such as

lamination, drilling, copper plating, etching and solder mask

application.

Advanced technologies such as laser drilling, advanced plating, and

multi-layer co-lamination are used in specialized PCB designs.

PCB Assembly & Soldering:

Electronic components are placed and soldered onto the PCB either

manually or automatically using techniques such as through-hole

soldering or surface mount soldering.

Reflow soldering and wave soldering are common automated processes

for connecting components.

Testing & Quality Control:

The PCB undergoes various testing and inspection processes such as

visual inspection, electrical testing, and functional testing to

ensure its reliability and performance.

Quality control measures, such as in-process inspections and

design-for-manufacturability (DFM) practices, help maintain high

standards in PCB production.

Electronic PCBs are used in a wide variety of applications, including consumer

electronics, industrial equipment, automotive systems, medical

devices, aerospace and telecommunications equipment, and more.

Continuing advances in PCB technology, such as the development of

high-density interconnect (HDI) PCBs and flexible PCBs, have

enabled the creation of smaller, more powerful, and more

energy-efficient electronic devices.

Circuit Board Pictures

|