| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Low Pressure Foam Machine |

|---|---|

| Brand Name: | ZHMACH |

| Model Number: | ZFP-2017 |

| Certification: | CE Certificate |

| Place of Origin: | Guangdong China (Mainland) |

| MOQ: | one set |

| Price: | inquiry |

| Supply Ability: | One set per month |

| Delivery Time: | 45 days |

| Packaging Details: | Paper and Film, Wooden case The whole set of one standard 13groups need 1*20GP and 2*40HQ. |

| The whole produce-line: | Steel |

| Produce-line frame, conveyer line: | Square tube |

| Oven Length: | 18M |

| Cold-hot water machine: | Refrigeration 10HP,electro thermal 36kw |

| FA10-25F glass flow meter: | 600~6000L/H |

| Dinner coveyer length: | 18m |

| Fall plate: | 7 section adjustable |

| Engineers available to service machinery overseas: | Φ25*2000mm |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Company Info. |

| Dongguan Zehui machinery equipment co., ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

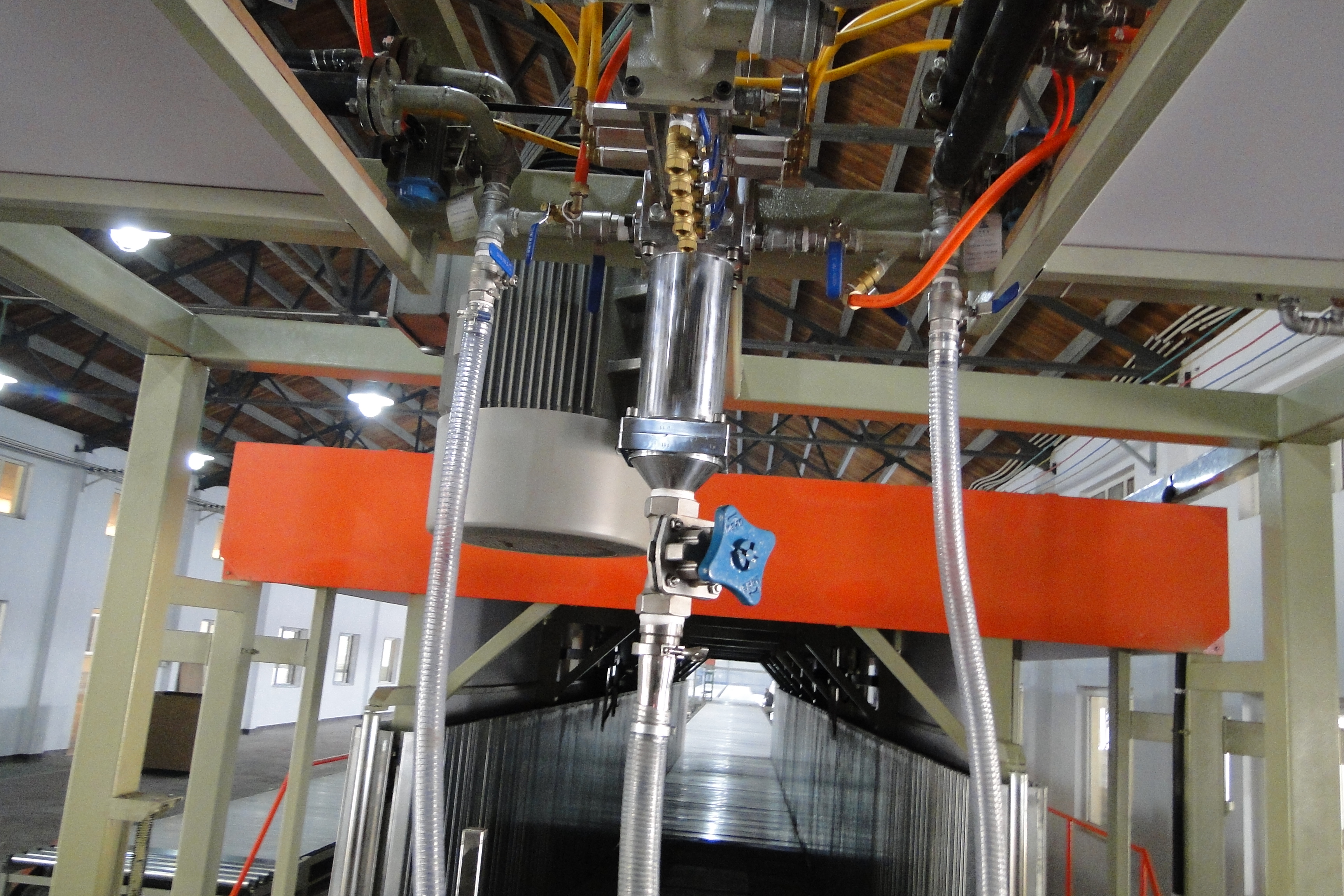

Horizontal Low Pressure Foam Machine , Flexible Polyurethane Foaming Machine with Japaness Pump

Product Description

This foam production line is an automatic continous foaming machine

for producing flexible polyurethane foam used in furniture,shoe

material,packing,electron,garment and transportation

industrial.it's the ideal production equipment for large-scale

foaming.

1, Dimension:Total length 40m×Total width 4m×Total Height 3m

2, Foaming material Group: 13 groups, man-machine interface, both

manual and computerized control.

3, Foaming width: 980mm~2350mm

4, Foaming height: Max 1300mm

5, Foaming density: 8Kg/m³~100kg/m³

6, Foaming speed: 2000r/min~7000r/min

7, Max total output:300kg/min

8, Material spraying way:

① The way of down sprayer head (upper, down, front, back can be

adjusted)

② The way of trough overflow pipe.

9, Controlling way of foaming:

①PLC controlling, can continuously foaming two different formulas

in one time

②All inverter controlling foaming and work in phase with the

production line

③Oven declining board height and width can be adjusted by control

box.

④Oven side links width can be adjusted by control box.

10, Mixing –head motor: 37kw

11, Total power: About 90kw

[Specifications]

(1) The whole machine parts specifications:

| Oven Length | 18m |

| Foam Height | 1.0-1.25m |

| Foam Width | 1.0-2.25m |

| foam desity | 8-200kg/m³ |

| total power | 130KW |

| inner coveyer length | 18m |

| side board adjustable width | 0.98-2.3m |

| conveyer belt speed | 0-8m/min |

| fall plate | seven section adjustable |

| total output | 100-300kg/min |

| machine dimension | L33× W4.5 ×H3.2m |

Transducer Types:

| Model | Power/kw | Use | Qty | Brand |

| G120 | 37 | Mixing head | 1 | Siemens |

| G120 | 7.5 | POP, CaCo3 | 2 | Siemens |

| G120 | 5.5 | PPG, | 1 | Siemens |

| G120 | 4 | TDI, Flame retardant | 2 | Siemens |

| G120 | 2.2 | MC, color | 2 | Siemens |

| G120 | 1.5 | Water, Ann, Si, Tin, Color Anti-yellow etc | 7 | Siemens |

| G120 | 0.75 | Spray head | 1 | Siemens |

| VFD-B | 5.5/3.7/1.5 | Oven inner conveyer line,side conveyer line, cutting machine | 3 | Delta |

Package:

How is the packing of the machine?

The entire machine will be nude packing. Some of the parts will be pack in wooden case. Others will be simple pack with paper or foam sheet with plastic film.

How many container will be needed for the whole set of machine?

For the standard YAFA-Automatic continous foam machine Total three containers is enough 2*40HQ+1*20GP. In order to save the place and the cost of delivery we will also put some parts that inside the raw material tank.

We will try the best way to pack all the machine well and also save

the freight cost.

1. We will help to design the layout of the machine that put in

your factory.

2. We will send 2-4 experience engineers to install and testing the

machines.

3. We will teach your engineer how to operate the machine and how

to maintain the machines.

4. We will give you the machine operation manual and the best

formulation for target products that you are going to make.

5. We will help to buy the best raw material for making the foam if

you needed.

|