| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roll Forming Machinery |

|---|---|

| Place of Origin: | China |

| Brand Name: | FriendShip |

| Certification: | ISO |

| MOQ: | 1 sets |

| Price: | As per client requirements |

| Packaging Details: | Plastic film or wooden case |

| Delivery Time: | 30-60days |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 10sets per month |

| Company Info. |

| FRIENDSHIP MACHINERY CO,LTD |

| View Contact Details |

| Product List |

Character of main structure

Technical specification

| Item | Description |

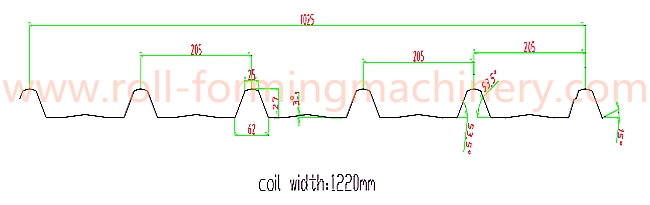

Coil width: | 1220mm |

Effective width | 1025mm |

Working speed: | 0-20m/min (not contain cutting) |

Roll station | 22 stations |

Material of roller | S45C polished and coated with hard chrome (0.007mm) |

Material of main shaft | 45﹟forge steel |

Diameter roller | Ф85mm |

Main power | 7.5KW machine |

Forming thickness | 0.25mm—0.8mm color steel and galvanized steel |

Voltage, Frequency, Phase | 415 V, 50 Hz, 3Phase |

| Control system | Siemens |

Transmission | by single line 1.2 inch Chains |

Feeding and guide | surface polished and coated with chrome (0.007mm) |

Machine adopt new station with chrome (at the up of each station have dial) | |

Size of machine | about 10500 x 1500 x1200 (L x W x H) |

Weight: | about 6500Kgs |

Color of machine | Blue(according customer requirement) |

Cutting process

12m auto stacker

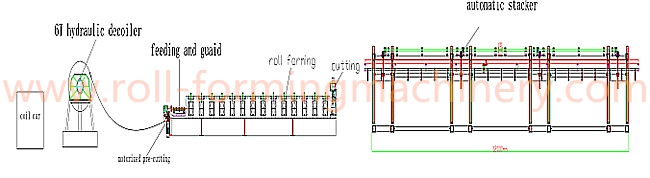

Composition of machine

NO. | NAME | UNIT | QTY |

1. | Roll forming main machine | SET | 1 |

2. | 6T hydraulic de-coiler with coil car | SET | 1 |

3. | Control panel | SET | 1 |

4. | Hydraulic station | SET | 1 |

5. | 12M auto stacker | SET | 1 |

6. | Spare tools | BOX | 1 |

Technological process

Decoiling—feeding—roll forming----make logo and cut to

length—product packing

manual

Profile:(Basis on customer’s require to design)

Some pictures of machine

Introduction of company

We, Friendship Machinery Co.,Ltd, attaches great importance on technology innovation,progress has been made on scientific management as well as Co.,culture.China leading expert in designing and manufacturing equipments for welding and cutting, automation system and metal works. We use and produce high-technology utilizing the most available robotic and automatic techniques. Every work is uncompromisingly designed to improve our clients' competitiveness and productivity.

We invest more on developing roll forming machine such as Metal roof & wall panels machines,C&Z purlin machines drywall Stud-track forming machines,Metal decks machines,No-girder and Column curves forming machine,Guard rails forming machines,Downspout pipes forming machines and so on.With fast development ,very short period for construction and beautiful external appearance,as well reasonable price was occupied in the market of building industry.

Contact Us

For more information, feel free to contact with us.

Skype:vivian_866

Mobile:86-15261519246

E-mail:sales02@roll-formingmachinery.com

vivianlucky866@gmail.com

|