| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roof Roll Forming Machine |

|---|---|

| Brand Name: | Shenghong |

| Model Number: | SWL151221-89 |

| Certification: | CE ISO |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1 sets |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 25 SETS/ MONTH |

| Delivery Time: | 40 days after payment |

| Packaging Details: | 1. Export standard package for container 2. Host nude, wheels with oil and gas bubble cushion packaging. 3. PLC controller with bubble cushion packaging 4. Spare parts in wooden cases. |

| Type: | Ridge Tile Roll Forming Machine |

| Main power: | 7.5 kw |

| Material type: | GI, GL, PPGI, PPGL |

| manual un-coiler: | 3 tons or Automatic un-coiler |

| Roll station: | 10-14 stations or depends on profile |

| Other components: | Schneider |

| Export Markets: | Global |

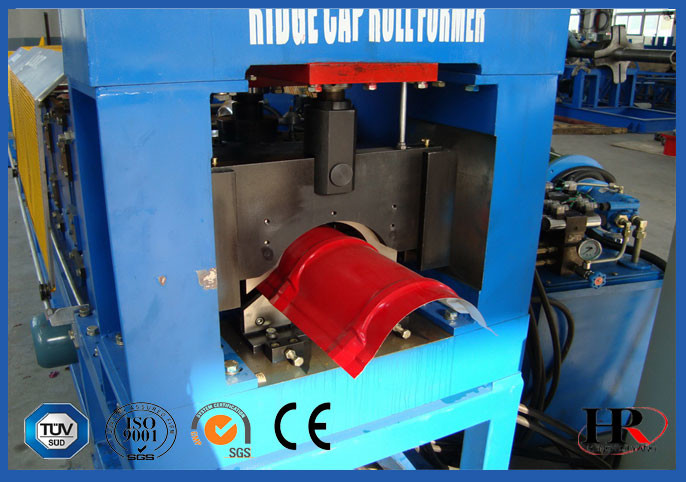

Efficient Rooftop Tile Cold Roll Forming Machine / Roof Tile Production Line

Basic Information

Introduction of Roof Tile Production Line

1. Component | |

Decoiler , Main roll forming system, Pressing device, Cutting device, Hydraulic station, PLC control | |

2. The general machine parameter | |

Suitable roll forming material | Color steel sheet or galvanized steel sheet |

Machine Sizes | 7800×900×1200mm |

Main motor power | 4KW with Cycloidal reducer |

Hydraulic station power | 4KW |

Roll forming thickness | 0.2mm~0.8mm |

Diameter of forming principal axis | Φ75mm |

Forming material expand width | 500mm |

Roll forming electric tension | 380V 3phase 50HZ or as the customer's requirements |

Material of forming roller | High grade 45# forged steel plated with hard chrome plating |

Roll forming speed | 2-3m/min |

Material of cutting | Cr12 mould steel with quenched treatment |

Kind of drive | 0.6 inch chain link bearing model 6210 |

Roll rows | 14 rollers |

3. Automatic PLC ( The PLC can be designed according to your requests) | |

Computer | Germany's "SIEMENS" or Japan's "MITSUBISHI" |

Encoder | Wuxi's "REP" |

Switch | CHNT |

Transducer | Germany's "SIEMENS"or Japan's "MITSUBISHI" |

Decoiler→Flating→Feeding & punching→Forming→cut-to-length →Colletion (Finished goods)

Raw material

| Material type | GI,GL,PPGI,PPGL |

| Thickness of coil | 0.3-0.8mm |

Our Service

We provide the technical support for whole life.

Meanwhile, if any parts go broken and not artificial damage, we

will send you new ones for free.

When need the technician to go abroad, we will arrange the

technician.

But the buyer should take all the cost, including Visa, Roundtrip

ticket,

suitable accommodation and pay the service fee.

Machinery Photos

Workshop Show

|