| Categories | Plastic Dryer Machine |

|---|---|

| Brand Name: | LIANDA |

| Model Number: | LDHW-100 |

| Certification: | CE,SGS,ISO9001 |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | USD 10,000-USD30,000 |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 30 sets per months |

| Delivery Time: | 30 working days |

| Packaging Details: | Factory standard package or customized package |

| Applied for: | PBAT ,PLA, PET, APET, APET, GPET, CPET, PLA, HIPS, PE, ABS, EVA ,PC, PEEK, PPS, PTFE, PEEK, TPU, TPE |

| Drying temperature: | can be adjustable by material property |

| Drying time: | 20mins (can be adjustable by moisture need) |

| Processing: | Dry and crystallization at a time |

| Heater: | Infrared lamps |

| Power source: | 380V 50hz 3PHASE or Customized |

| Control system: | Siemens PLC |

| Condition: | New |

| Warranty: | 1 year |

| Color: | custom-made |

| Company Info. |

| LIANDA Machinery Co.,Ltd. |

| View Contact Details |

| Product List |

Infrared Crystal Dryer for PBAT, PLA, PET, masterbatch, save energy costs 45-50%

Infrared drying principle:

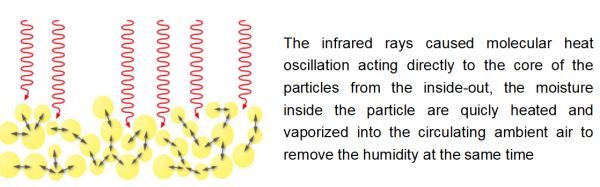

Infrared drying is a method of drying using radiation heat transfer. The electromagnetic wave generated by the infrared radiator travels straight at the speed of light to reach the material to be dried. When the frequency of infrared emission and the natural frequency of molecular movement in the material to be dried (that is, the emission wavelength of infrared rays and the absorption wavelength of the material to be dried) When matched, the molecules in the material vibrate strongly, and intense friction occurs inside the material to generate heat to achieve the purpose of drying.

In infrared drying, because the surface moisture in the dried material continuously evaporates and absorbs heat, the surface temperature of the material is reduced, causing the internal temperature of the material to be higher than the surface temperature, so that the thermal diffusion direction of the material is from the inside to the outside.

At the same time, the moisture moves due to the moisture gradient in the material, which always spreads from the interior with more moisture to the exterior with less moisture. Therefore, the direction of moisture diffusion and thermal diffusion within the material is the same, which speeds up the process of moisture diffusion, which speeds up the process of drying.

Because the depth of the radiation penetrating the object (the depth of heat penetration) is approximately equal to the wavelength, and the far infrared is shorter than the near infrared, which means that it is better to use far infrared to dry than near infrared. In particular, because the emission frequency of far-infrared rays matches the natural frequency of molecules of plastics, polymers, water and other substances, the molecules of these substances resonate violently. In this way, far infrared rays can penetrate into these heated and dried objects and are easily absorbed by these substances. Therefore, far infrared rays are better for drying than the two.

Our IRD ( Infrared Dryer ) will make for you

(Re-cooling the pellets to avoid the pellets re-moistured )

Our Advantage

Infrared Crystal Dryer | Conventional Crystallizer | |

| 1 | Easy to clean The drum can be opened completely,no hidden spots and can be cleaned easily with a vacuum cleaner | Have to be completely disassembled,cleaned and fixed |

| 2 | Rotary drying system, its rotating speed can be increased as high as possible to get an excellent mixing of pellets. It is good in agitation, the masterbatch will not be clumped | Poor agitation,easy to be clumped |

| 3 | Can satisfy different type of Masterbatch (Drying temperature and time can be adjustable by the property of raw material) | The drying temperature is fixed |

| 4 | Crystallization time 15-20mins depends on the material kind | Need 4-6 hours or more |

| 5 | Save about 40% energy consumption compared to conventional dehumidifier | |

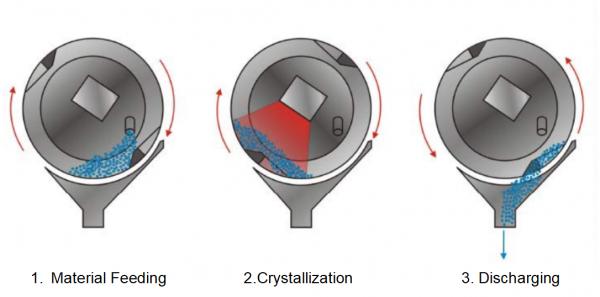

How Lianda Infrared dryer to crystallize

Machine detials:

HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped

with a variety of professional processing equipment and we have

accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by

inspecting personnel.

● Each assembly is in charged by a master who has working

experience for more than 20 years

●After all the equipment are completed, we will connect all the

machines and run the full production line to ensure the stable

running in customers' factory

Why Choose us

1. We are professional manufacturer of plastic recycling and have professional technical team, focus on provide high quality equipment and good service for customer.

2. Our plant with area of 7600 square meters, 62 employees. All skill workers have professional skills certificates.

3. We have professional production QC team to ensure the machine manufacturing quality.

4. All equipment are running test before shipment.

5. During customer visit, we can take customer to our customer ‘s factory to looking machine working.

6. We imported Germany PET infraraed technology and got production

patent in China on 2008. On this basis, research and development

and improvement have solved the problem of material leakage in the

production process.

Our Service![]()

1. We will provide testing if the customer comes to visit factory

to see the machine.

2. We will provide detail machine technical specification ,electric

diagram,installation,operation manual and all the documents which

customer needed for clearing customs and using the machine.

3. We will provide engineers for helping installation and training

the workers at customer's site.

4. Spare parts are available when they are needed .Within warranty

time,we we will provide spare parts free,and over warranty time,we

will provide spare parts with factory price.

5. We will provide technical support and repair service in the

whole lifetime .

Contact Us

|